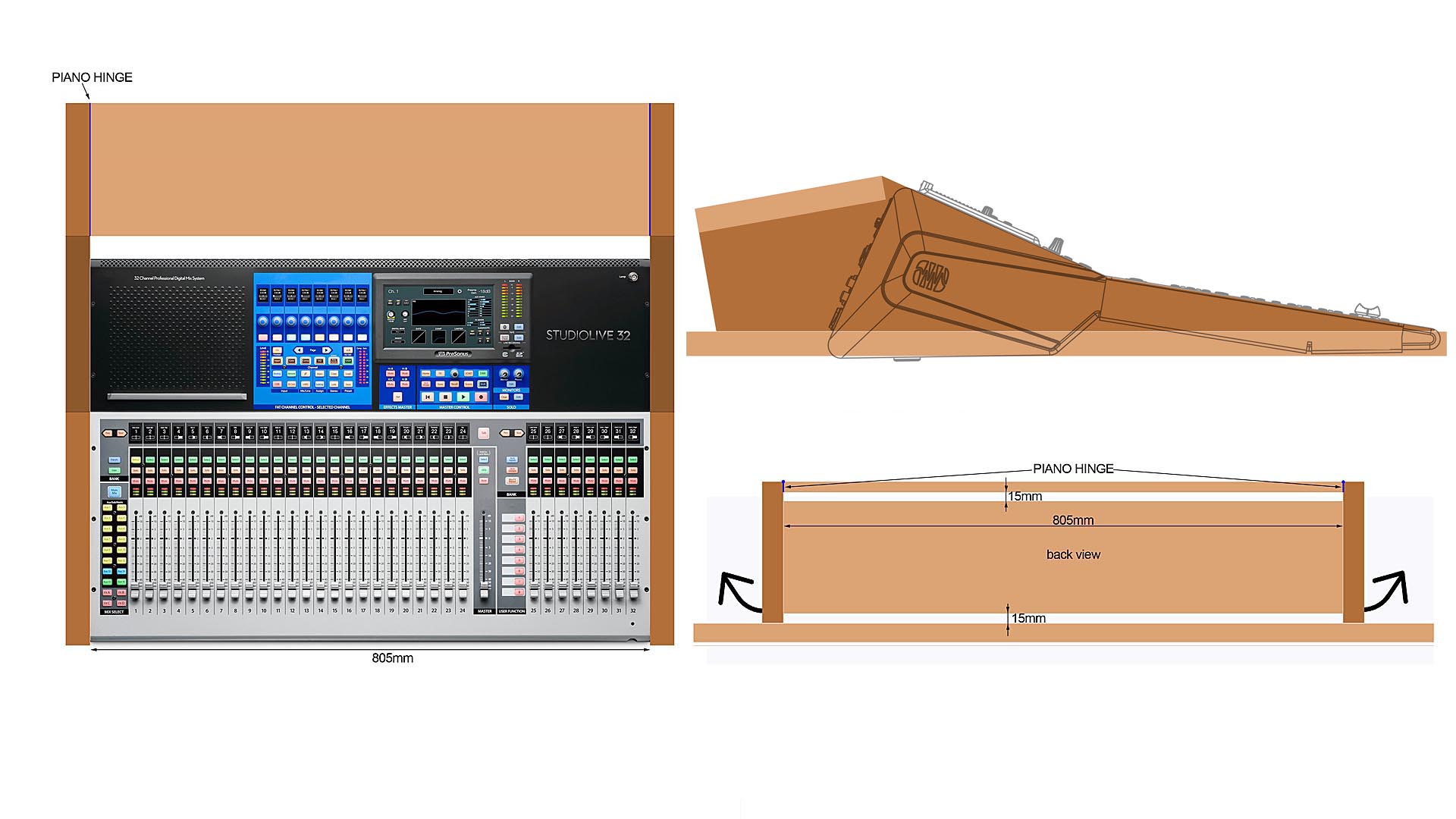

Modifying the Presonus Studio Live 32 Mklll digital mixing console

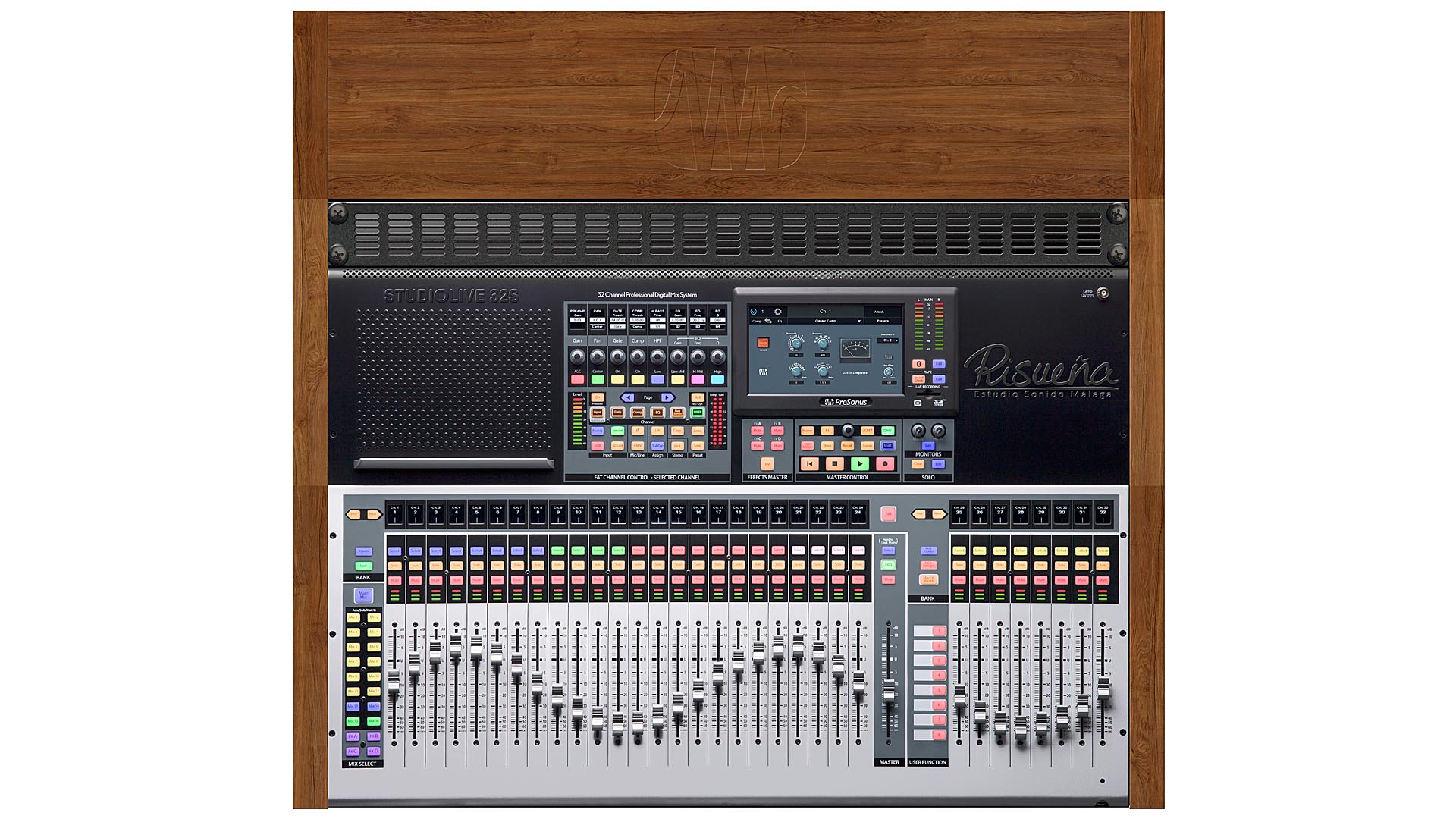

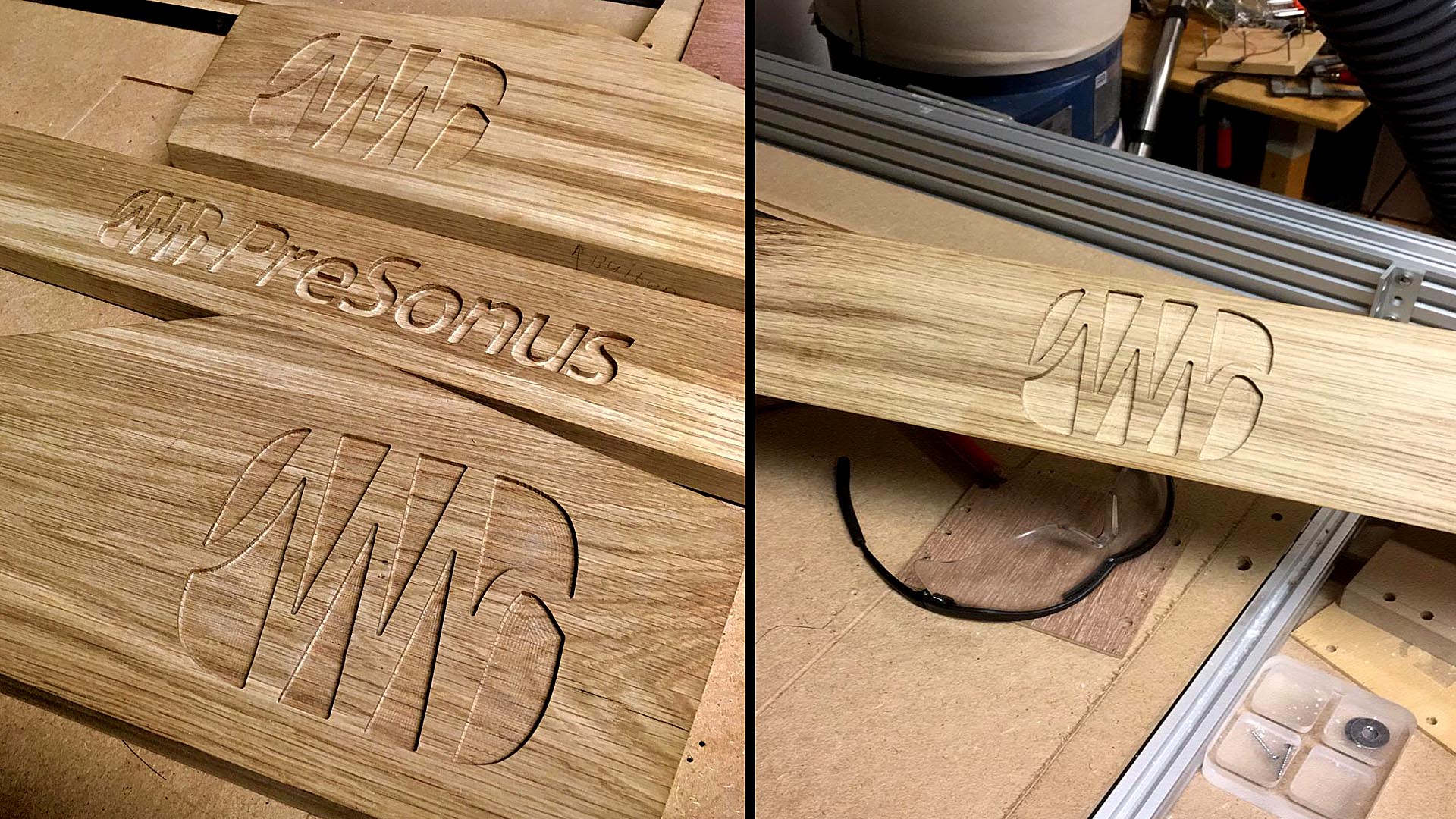

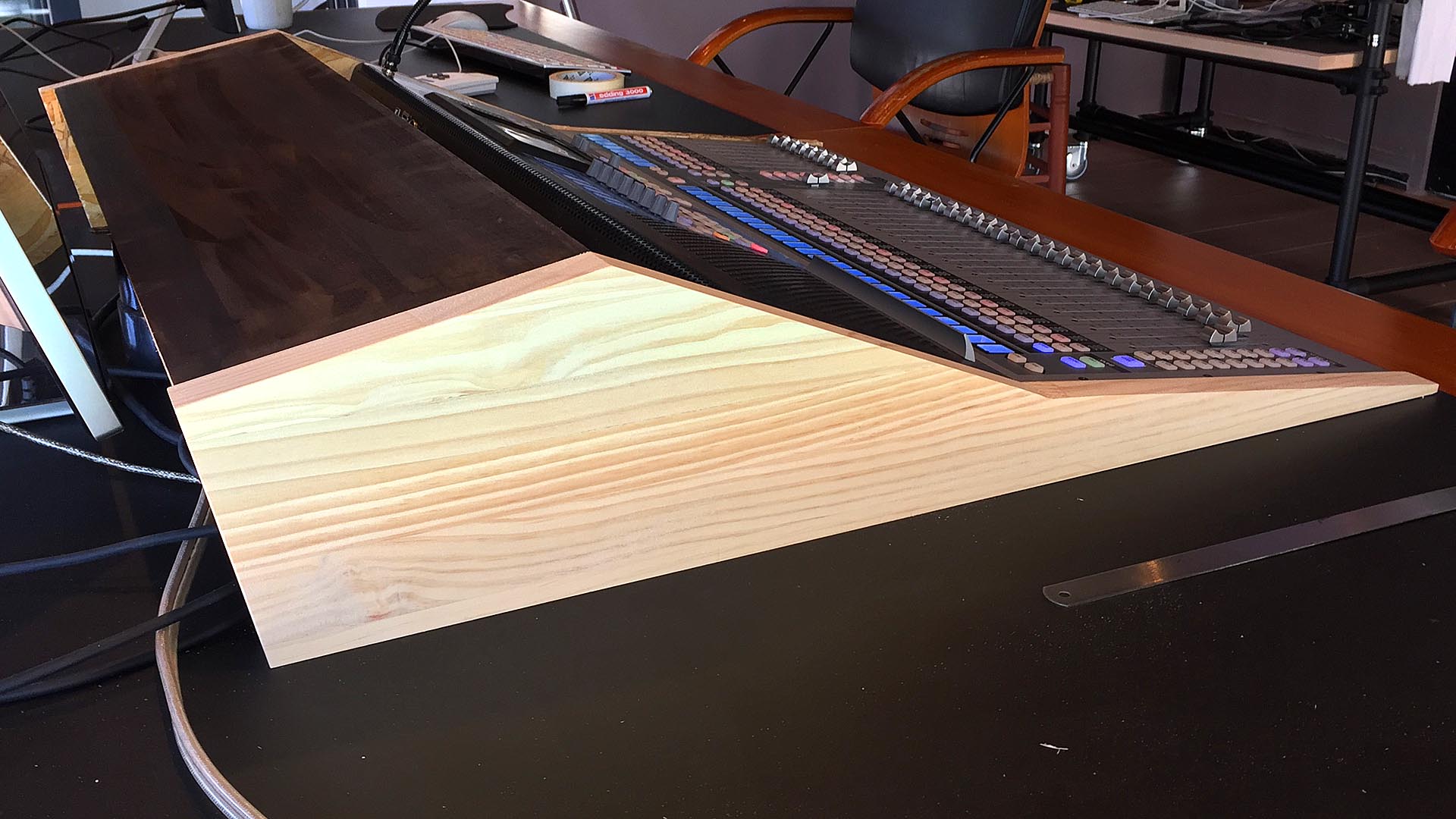

We build wooden cheeks for our Presonus mixing console.

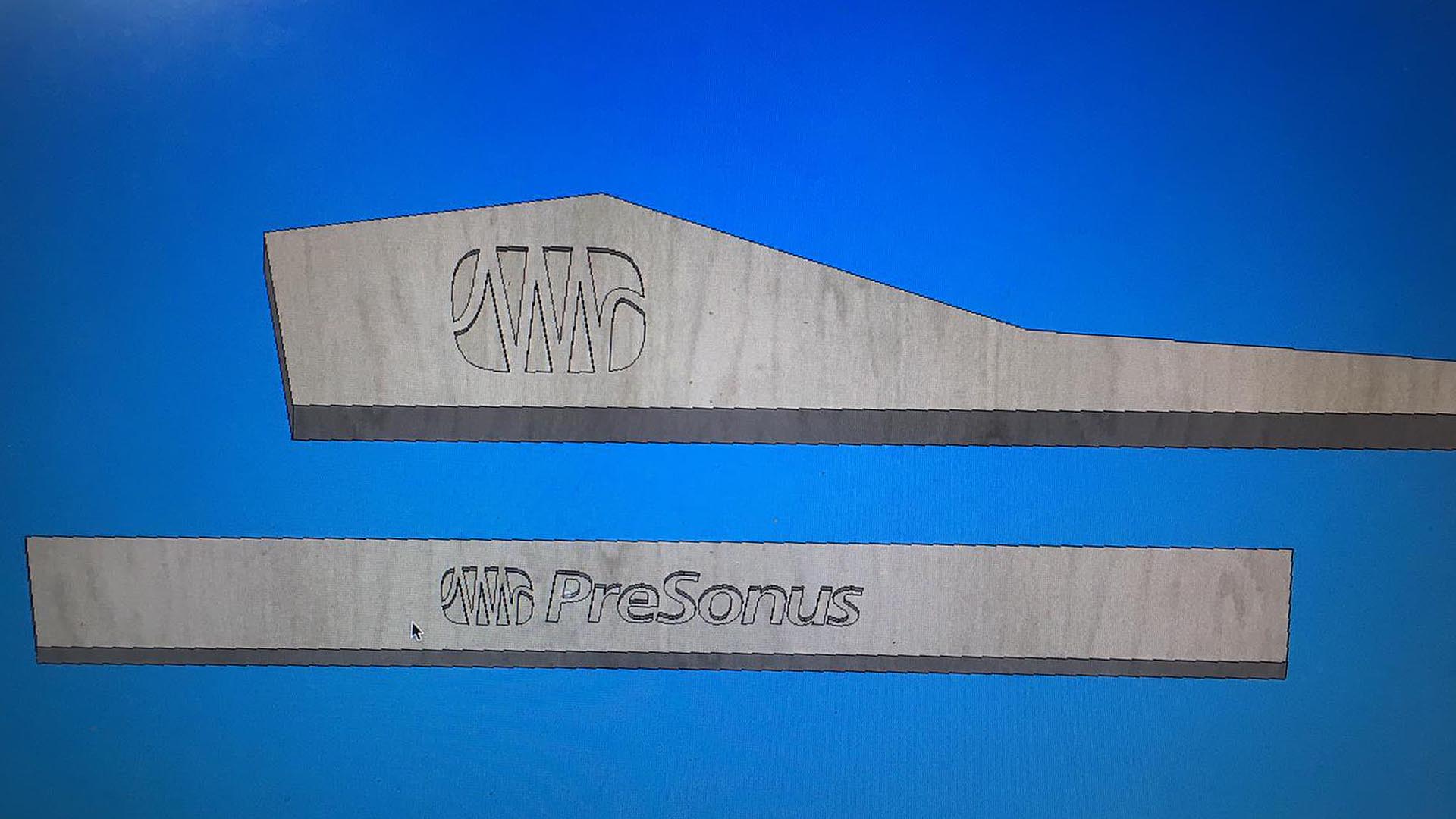

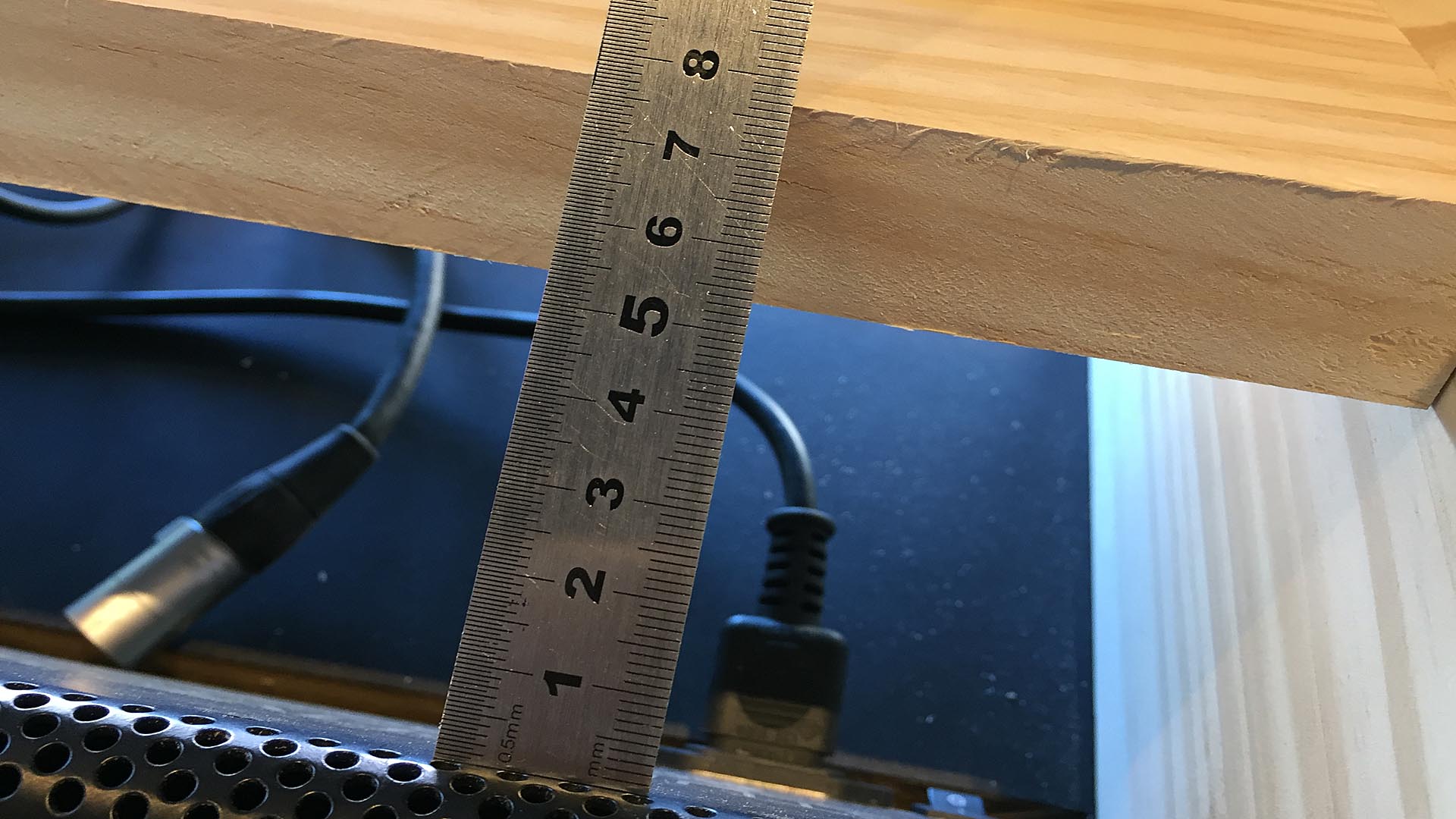

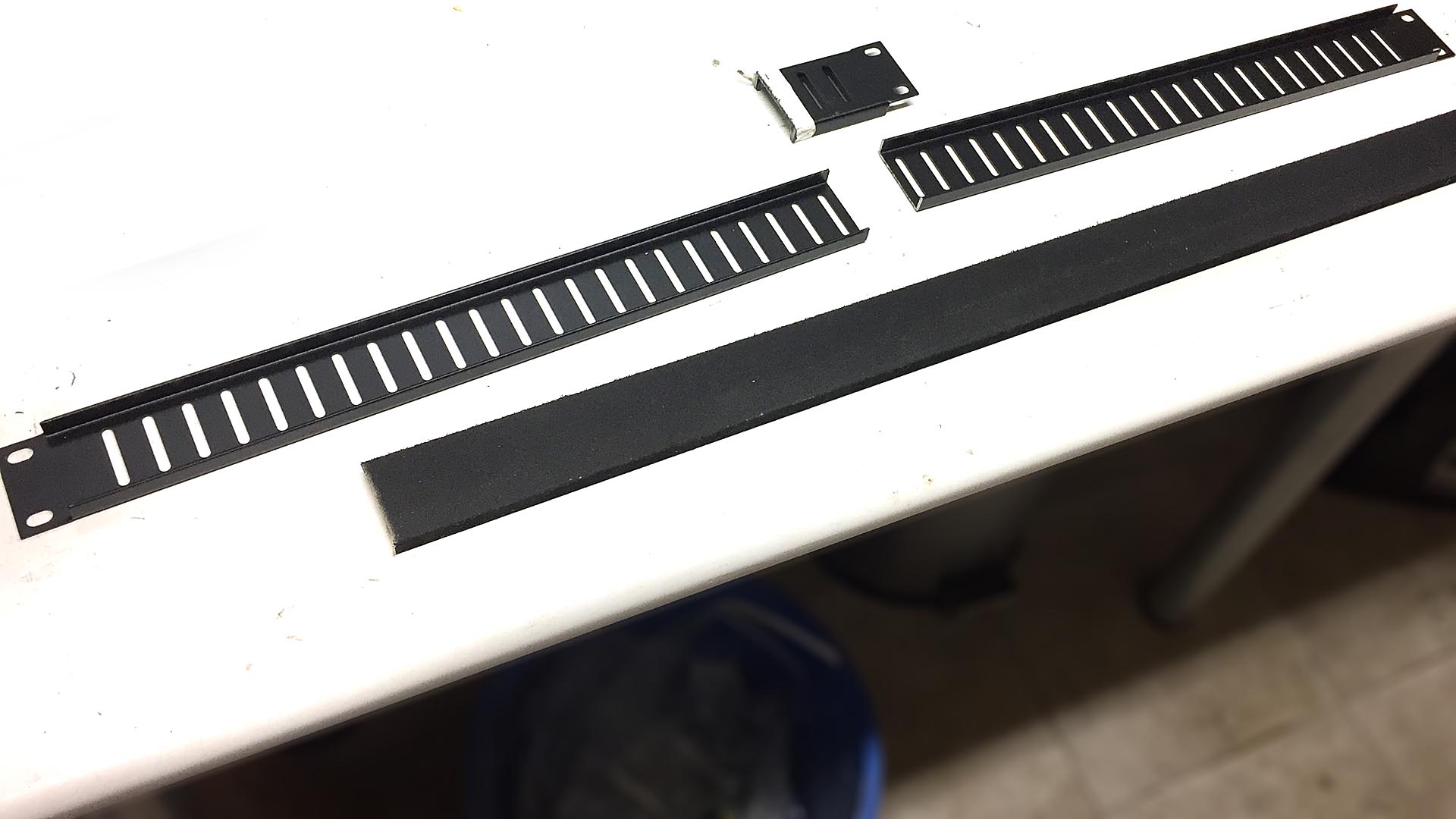

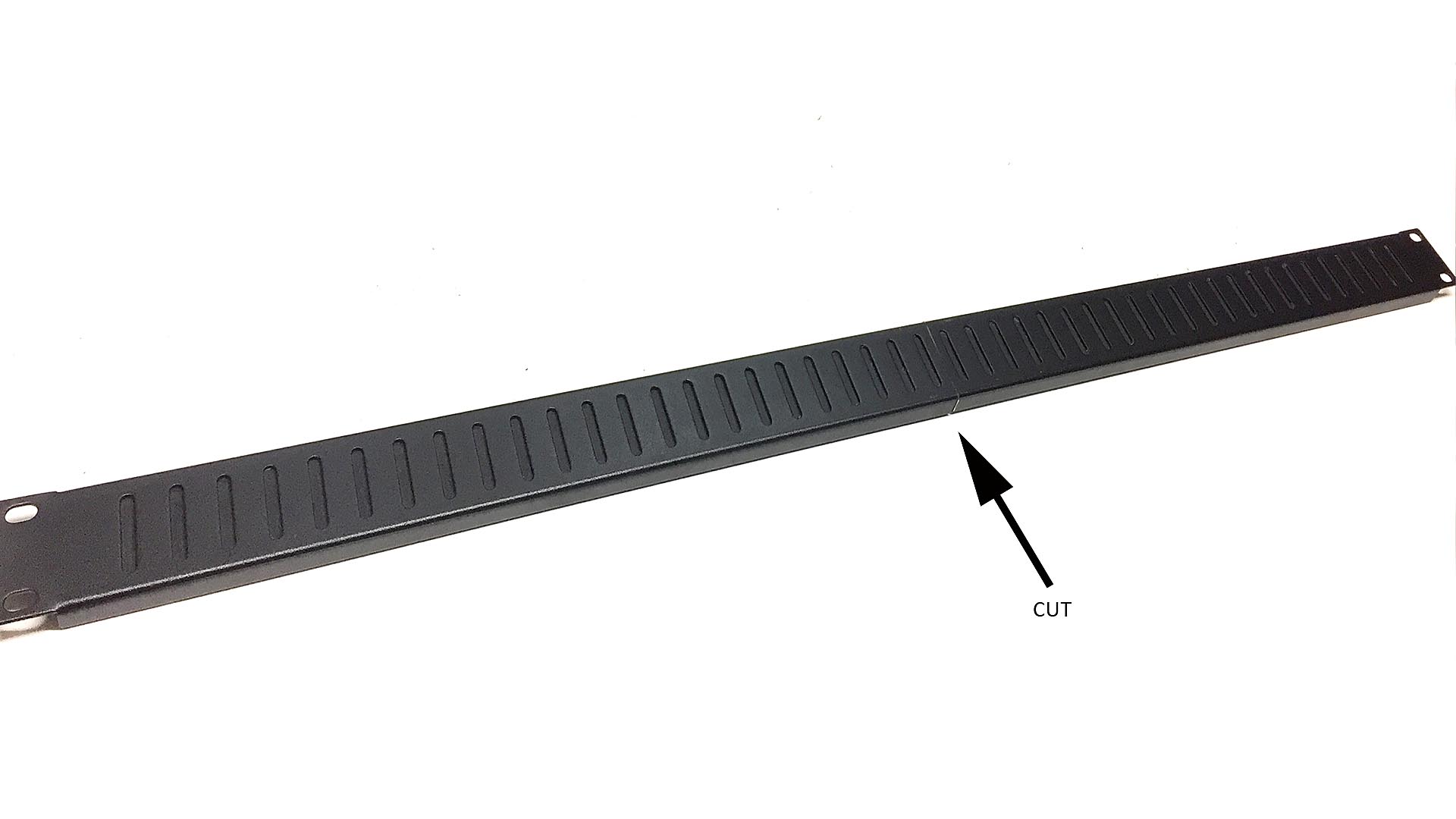

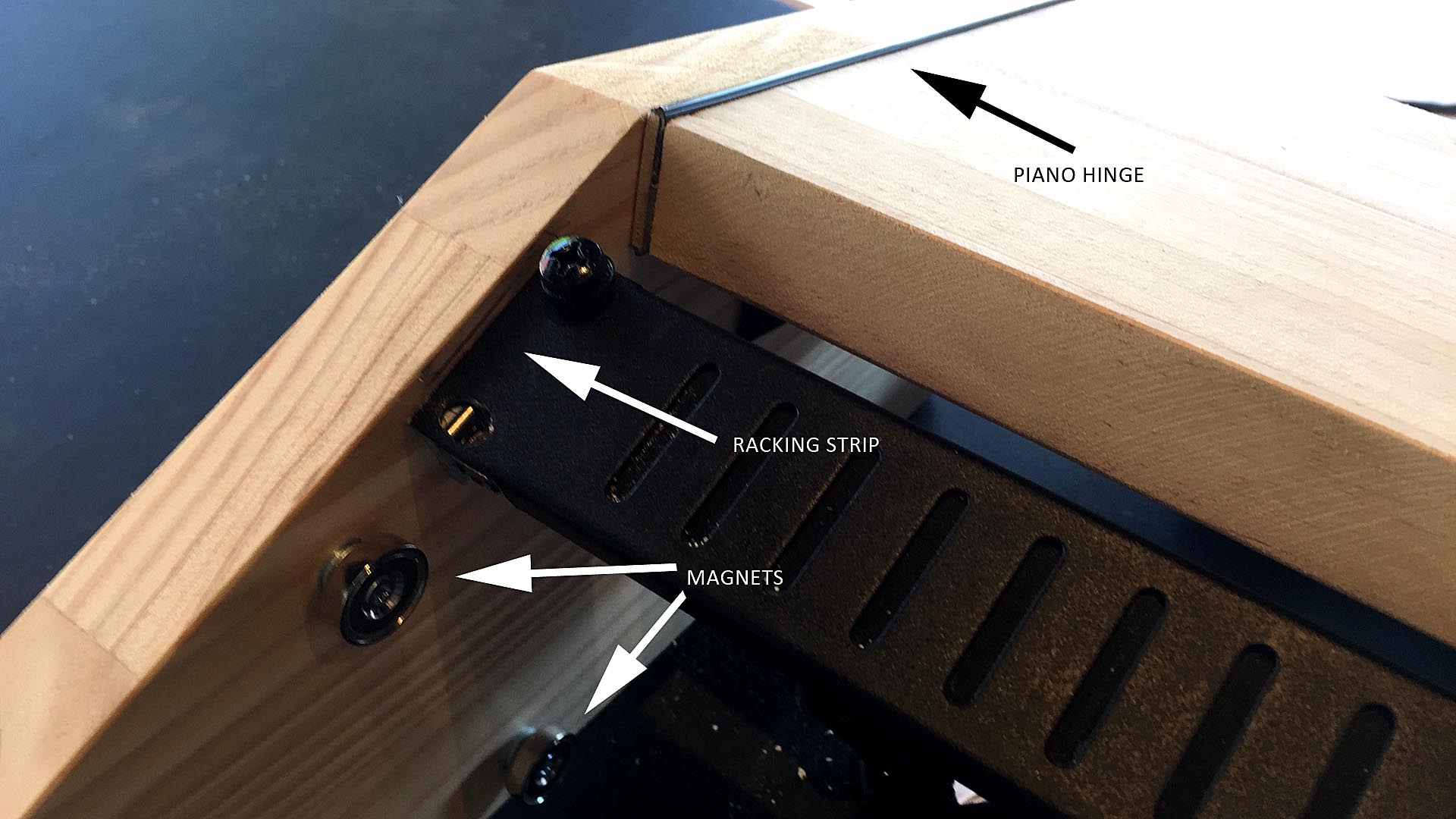

See our photo’s below with constructions details and measurements. Some prototypes were build before the final product was approved. We finally liked the oak console best. In the same batch we made cheeks for a few Behringer synths.

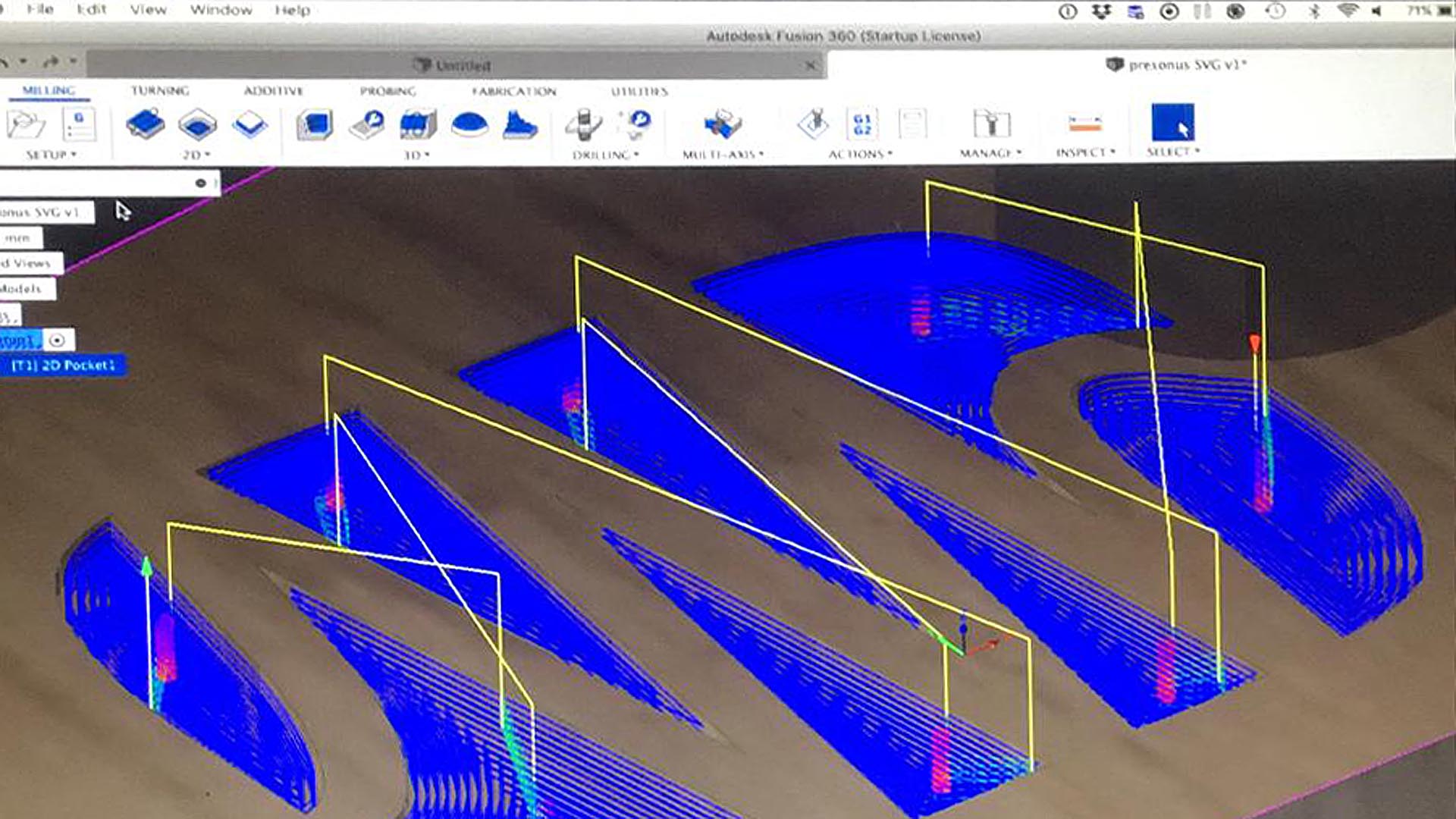

See pictures below for all stages of the design. Click image for more details.

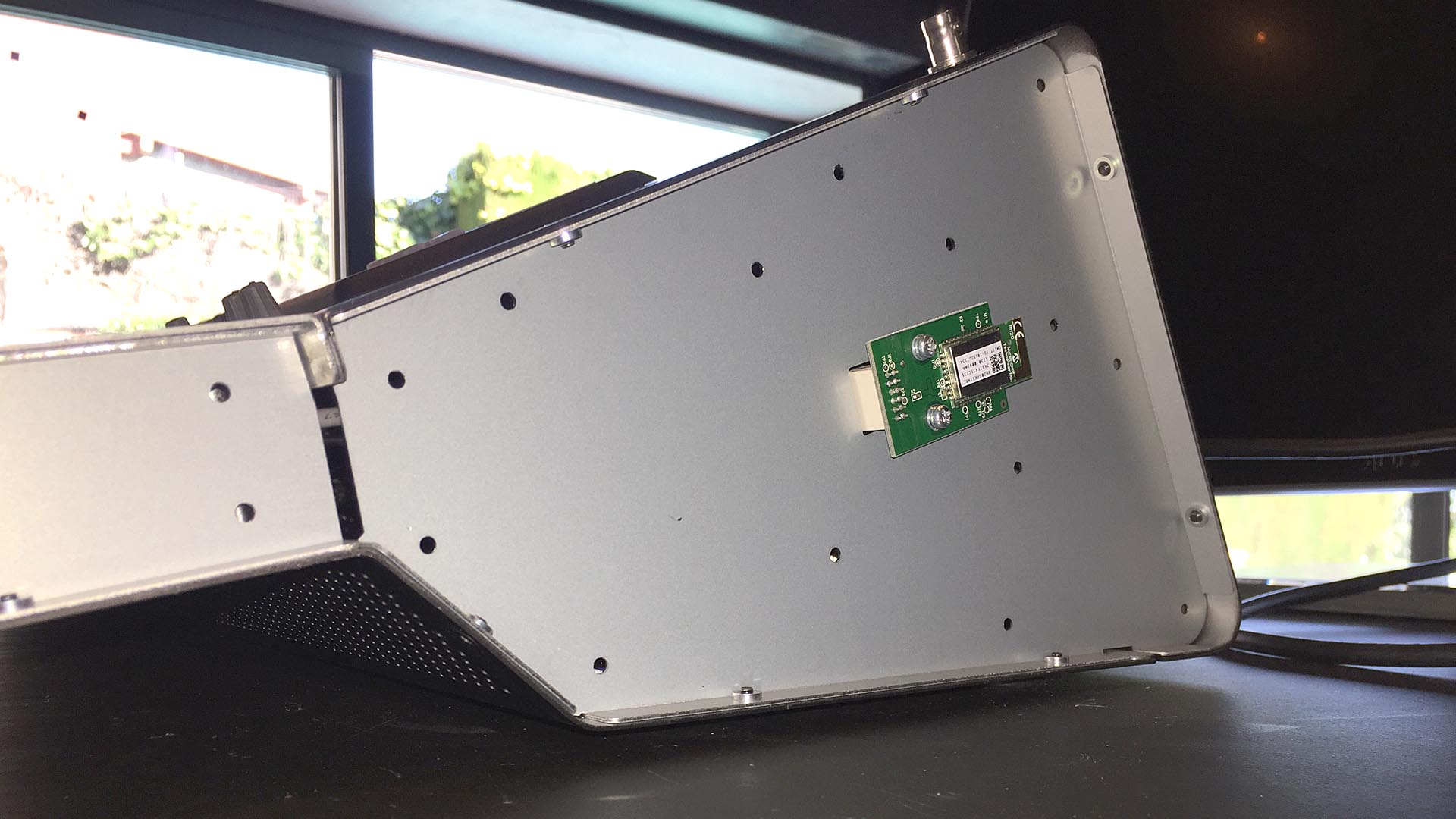

To remove the plastic cheeks first unscrew the little bolds out of the top face plate of the mixer. Then separate the plastic cheeks from the metal counter part. Again a lot of Philips screws to be removed. Then put back the metal cheek only.

Because of the chassis is all metal, magnets can be used to clamp the wooden cheeks to the mixer,